Manufacturing process

Design room

Taesung Industrial Co., Ltd. reflects the importance of design in practice in the market with individualization of consumers and the fierce market. Investment in design becomes an important success factor.

In the reality that production volumes are gradually decreasing due to the individualization of consumers and the fierce market, investment in design becomes an important success factor. Taesung Industrial Co., Ltd. is striving to increase the added value of products by establishing its own design department by reflecting the importance of design in practice and creating beautiful images. It leads the sensitive market by creating an autonomous image that is out of the frame of order (OEM), and has the valuable ability to digest the design of the orderer through the best motivation for design. The win or loss of your cosmetics is in design.

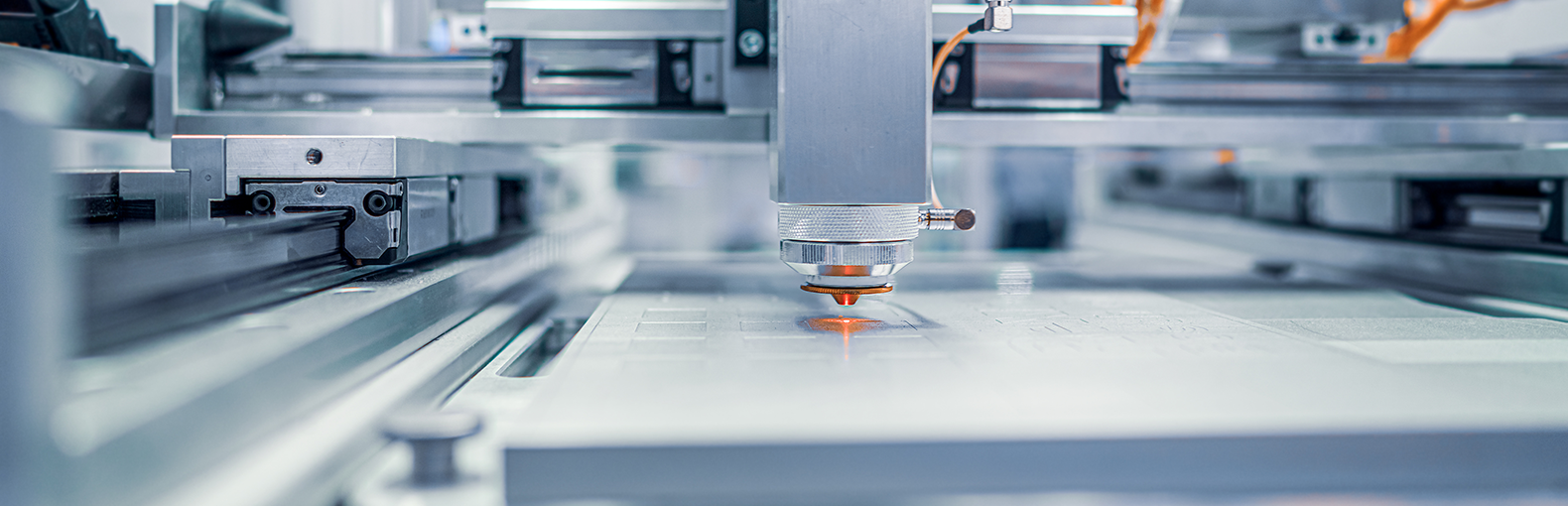

Mold production

Taesung Industrial Co., Ltd. promises to implement the company-wide quality management with not only quality control at the product site, but also comprehensive quality control.

The Quality Management Department, which applies scientific principles to maintain and improve product quality, has focused on maintaining and improving product quality at the manufacturing site as the main management goal, including quality inspection. However, under the idea that the quality of the product itself cannot be improved unless the quality is improved throughout the work of each field, which is now concentrated on the product, not only the idea of not producing defective products by thorough quality control at the product site, A company-wide management method is applied to improve the quality of business performance across all non-manufacturing sectors such as sales, planning, creativity, general affairs, and accounting. This comprehensive quality control is spreading not only in manufacturing, but also in industries such as construction, distribution, and service. In particular, the US has expanded the concept to actively accept and install it as TQM (Company Quality Management). We, Taesung Industry, promise to realize perfect quality for your products through standard (export) inspection based on the unit production volume, including company-wide quality management, and precision measurement equipment including vacuum testers and heat-resistant testers.

Injection

Taesung Industrial Co., Ltd. is capable of producing products that meet the purpose by possessing injection molding machines, molds, and raw materials, which are the main elements of injection molding, and is working on production with its own precisely manufactured molds.

Injection, which refers to plasticizing by applying heat to plastic to make a product by shooting a molten resin into a mold by hydraulic pressure, requires various complex related facilities for injection molding where the product is directly made, but especially injection molding machine, mold, Raw materials must be prepared. When the characteristics of these three elements are harmonized, injection molding is possible, and products that meet the purpose can be produced. We, Taesung Industrial Co., Ltd. are working on production with actual injection molding machines (Hyundai), and are working on production using Samsung and LG raw materials in their own precisely manufactured molds.

Post-processing department

Post-processing of the injected product is also an important process in determining the quality of cosmetic containers. Taesung Co., Ltd. continues to expand the factory and meet the line of post-processing products.

Post-processing of the injected product is also an important process in determining the quality of cosmetic containers. Taesung Co., Ltd. continues to expand the factory and meet the line of post-processing products.

Assembly

Taesung Industrial Co., Ltd. has achieved automation of assembly facilities with manpower with many years of experience. We will add a neat assembly to your products under the idea that even a small thing has a big impact on quality.

Taesung Industrial Co., Ltd. has achieved automation of assembly facilities with manpower with many years of experience. We will add a neat assembly to your products under the idea that even a small thing has a big impact on quality.

Quality Management Department

We promise to realize perfect quality through company-wide quality management, sample inspection, and precision measurement equipment such as vacuum tester and heat resistance tester.

The Quality Management Department, which applies scientific principles to maintain and improve product quality, has focused on maintaining and improving product quality at the manufacturing site as the main management goal, including quality inspection. However, under the idea that the quality of the product itself cannot be improved unless the quality is improved throughout the work of each field, which is now concentrated on the product, not only the idea of not producing defective products by thorough quality control at the product site, A company-wide management method is applied to improve the quality of business performance across all non-manufacturing sectors such as sales, planning, creativity, general affairs, and accounting. This comprehensive quality control is spreading not only to the manufacturing industry, but also to industries such as construction, distribution, and service. In particular, the United States is expanding its concept and actively accepting and installing it as TQM (Enterprise Quality Management). We, Taesung Industry, promise to realize perfect quality for your products through standard (export) inspection based on the unit production volume, including company-wide quality management, and precision measurement equipment including vacuum testers and heat-resistant testers.